6 minutes read

•

January 31, 2025

With more than 90 operational units, activities in more than 100 airports throughout the country, appreciation for innovation and continuous improvement of processes, Vibra Energia, formerly known as BR Distribuidora, has more than five decades of history and tradition as a leader in the fuel distribution and lubricants market in Brazil.

In 2019, Vibra created its innovation hub with the goal of connecting and collaborating with startups to develop solutions that would meet the company's new business and challenges.

It was from this initiative that Vibra learned about the customized solutions of Smarthis, a true operational revolution in the company.

The partnership was established for the development of automation of repetitive activities, which occupied long days in necessary tasks, but with low return. The results, however, went much further.

The performance of Smarthis for the development and implementation of RPA processes in Vibra, underwent the following phases:

Mapping: before starting the project, Smarthis surveys and identifies the processes that may be candidates for undergoing automation. In other words, those that have well-defined parameters, high recurrence and high return potential.

Design: this is where the planning of the project model takes place, from the optimization of the current activity flow to the analysis of the user interaction screens and the creation of the automation schema.

Validation: the technical capability of automation is verified in relation to the volume of activities to be performed.

Development: the process automation system is built by the development team, once the activities and data from the previous phase have been analyzed.

Assisted operation: the moment when automation starts to operate in a controlled way, in consecutive and uninterrupted cycles, testing all the scenarios that may occur during the processes.

Production: after the test flow, the improvements are made and their results ensure that the automation will handle all the existing variables and execute the solutions successfully.

The first automated processes occurred in the financial sector of Vibra. However, within a few months, the APR projects were already in motion in the production chain of the distributor, in processes that returned gains that are even more significant in hours of manual labor.

These replicable and/or simultaneous routines took place in different bases throughout Brazil.

An example of these activities is the stock closing report, where every day in each of the country's bases an administrative assistant would check the levels of fuel in reserve and then make the comparison with the accounting report.

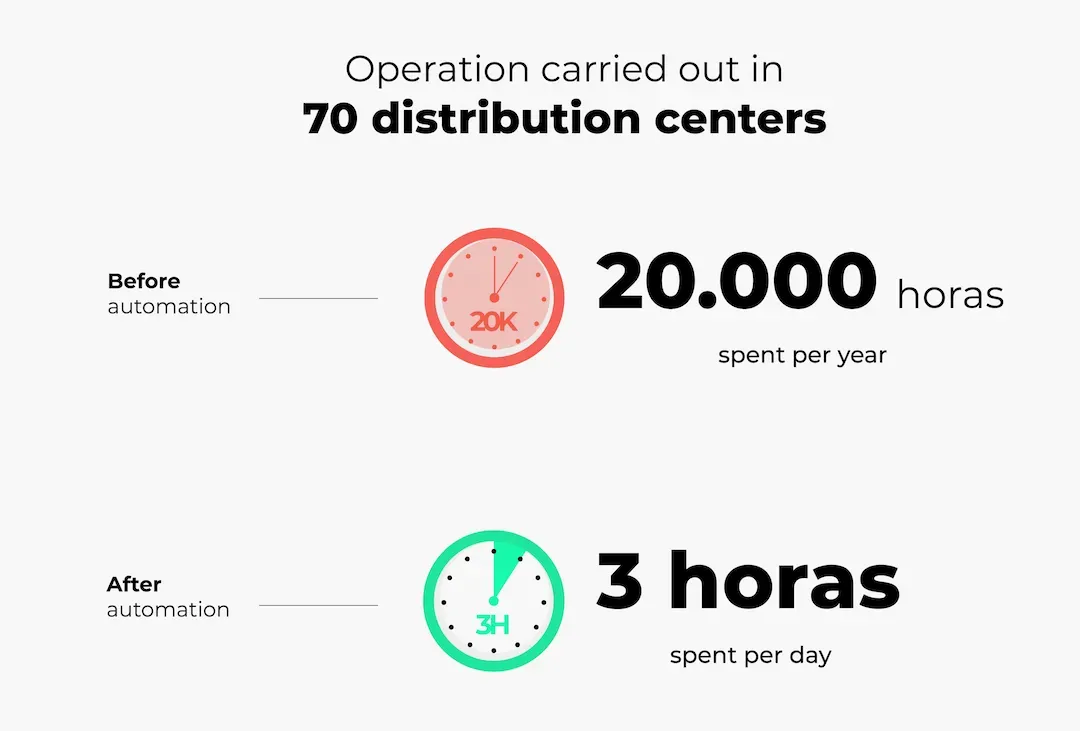

This same operation was performed in 70 distribution centers, taking more than 1 hour in each to be completed. Over the year, a total of 20 thousand hours were spent in this procedure alone.

After the automation of this process, within only 3 hours RPA the stock is checked and validated in all the units in the country!

After all the success of RPA projects at Vibra, the team received a name and mascot: Br@x. It carries the concept that manual and repetitive activities that can be automated, go from A to X; while, Y and Z are the tasks of creativity and innovation, where the human focus should be to add value to the business.

Currently, Br@x is implemented in 160 processes, within 40 areas of the company, saving up to 380 thousand hours of work per year.

A Smarthis differential that is essential for the efficient functioning of the project, and that guarantees such expressive results, is the speed in presenting the solutions. Each project took, on average, only 6 weeks between the design development phases until it went live.

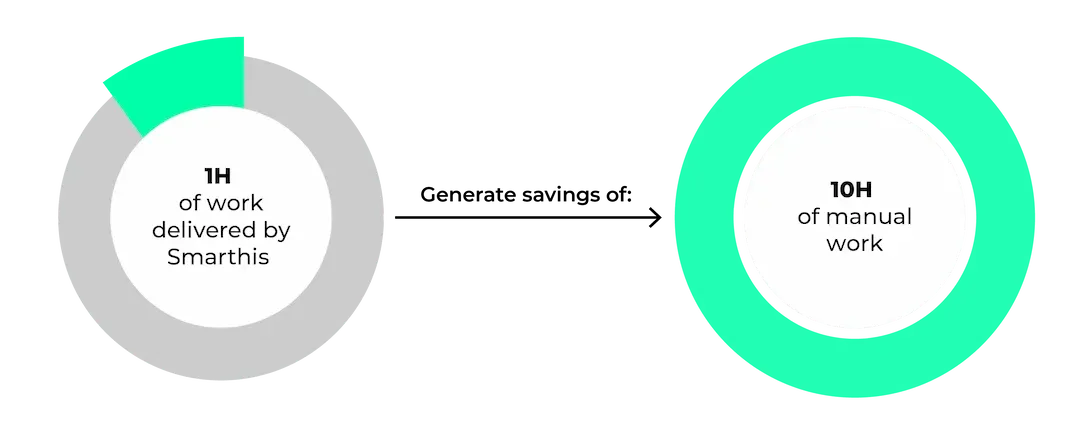

Based on the data analysis of the project, one hour of the work delivered by us generates savings of 10 hours of manual labor for Vibra, time that is reallocated to more strategic activities that generate more value for the company.

After 3 years, the partnership with Vibra has advanced to a new level. We work together throughout the development and the governance of the automations; dealing with the security of data and information, performing uninterrupted monitoring for identification and resolution of incidents and documentation of the APR projects, as well as adding to the team business analysts to act actively in the continuous improvement of the company.

What started as an experimental project became part of Vibra Energia's strategy, making Smarthis very proud of the opportunity, trust, and partnership.

Explore our content